Our facility is thoughtfully designed to support high-quality model making at every stage. Equipped with advanced tools like 3D printers, CNC routers, and laser cutters, it supports our team to work flawlessly while attending every detail with absolute precision.

Each division plays a role in creating and changing concepts of huge ideas to stunning models, this includes carpentry and paint to digital workstations and finishing bays. This makes our workspace functional and an easy playce to conceptualise.

Our workspace is built to support accuracy, speed, and creativity.

With the right tools in place, the team can focus on bringing each model to life with skill and detail.

Our editing & designing team have the expertise to meticulously review, edit and design with received client drawings. This enables us to meet our client’s desire in respect to size, scale and representation of the design in miniature.

Our fleet of machinery includes high-quality laser cutting and engraving machines, CNC engravers, CNC routers and 3D prototyping machines. These facilitate in accomplishing the forming of complex shapes and designs.

When our talented carpenters handle the machines, every complex geometry becomes feasible.

Constructing the structure of the model and fabricating the sub assembly is an important element of model making. Our real strength lies here with the induction of a large number of model making technicians.

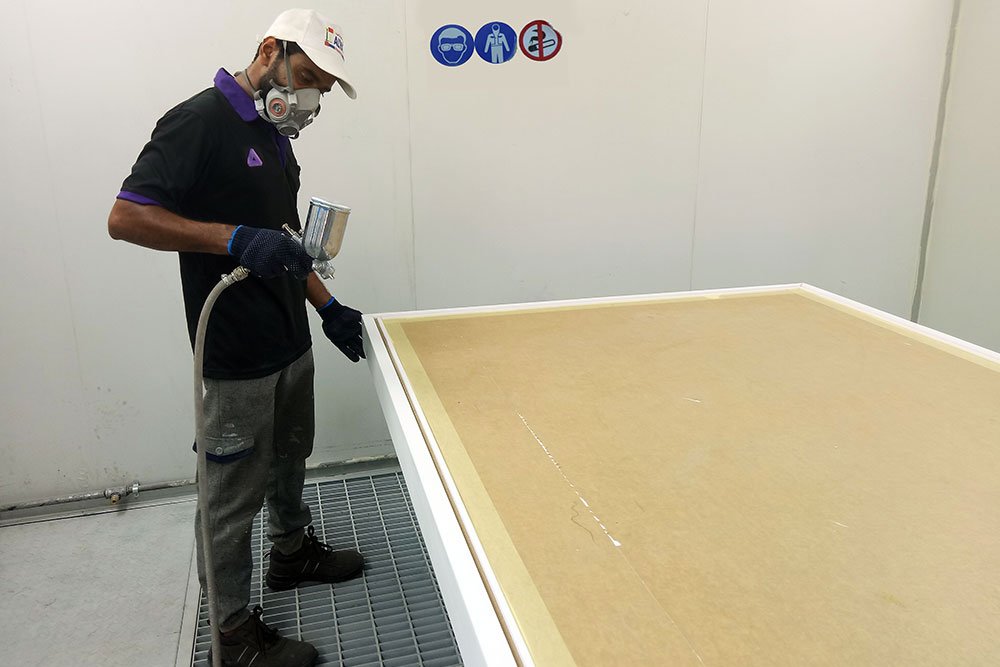

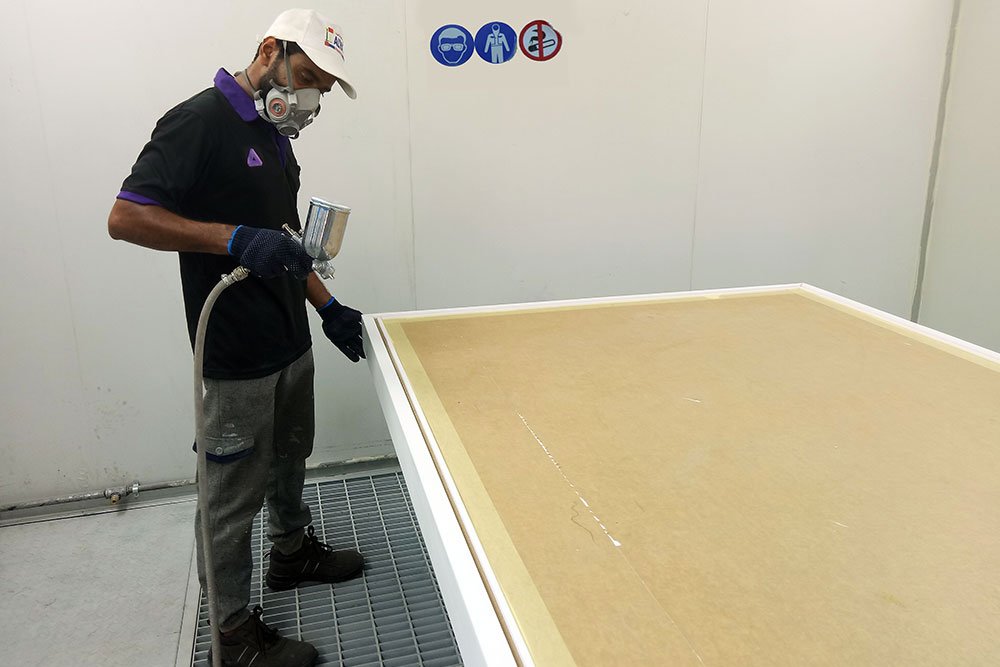

The multi-stage painting booths installed in our facility ensures a clean quality paint finish to our products. Our painting technicians have gifted hands to apply an artistic touch to the model finish.

The trend and highlight of contemporary scale models are their spectacular lighting features. Over the years the incorporation of various lighting sources like addressable LEDs have made the physical scale model an interactive element with remote control devices like iPads, Android tablets, and touchscreen systems.

In the final assembly all fabricated sub-assemblies, various lighting features, accessories, soft and hard landscaping come together to shape the model. With our large team and workspace, we have the ability to assemble many models simultaneously.

We have a large in-house landscaping material manufacturing capacity in our facility. Our skilled artistic team are proficient enough to make any specific soft and hard landscaping requirement.

We have a talented artistic team to apply just the right touch of embellishments to any model scenario. The life and soul of a model are transformed through the use of embellishments. Hence we give high priority to make our models adorable.

Our packing crates and flight cases are made to international standards. Our flight cases are custom made to ensure the safe travel by all means of road, sea and air transport.

We have a large in-house landscaping material manufacturing capacity in our facility. Our skilled artistic team are proficient enough to make any specific soft and hard landscaping requirement.

Please contact us using the form and we’ll get back to you as soon as possible.